Ultrasonic Cleaning Lines for cleaning

wafers after cutting.

Ultratech, spol. s r.o. is producer of

ultrasonic cleaning tanks and lines for final cleaning wafers after wire saw

cutting processes. During last

several years our cleaning lines were

manufactured, delivered and put into operation at our customers’ plants in e.g.

The machines have modular construction which

allows us to set the machines as “tailor made” under customers’ requests.

Main technical parameters of standard cleaning

tanks for final cleaning wafers after cutting processes:

-

Inner tank dimensions: 660 x 400 x 390 (L x W x H) mm (Possible tank size under

customers’ request.)

-

Tank volume: 70 or

-

Acoustic power: 25W/l

![]() Ultrasonic cleaners for final cleaning silicon wafers

after cutting:

Ultrasonic cleaners for final cleaning silicon wafers

after cutting:

![]() Manually operated cleaners:

Manually operated cleaners:

They

are suitable mainly for producers with lower production capacity.

Production

range is from one bath cleaners up to line with several

Possible accessories:

- Baskets

- The Hot air dryer S 105

- Waggling mechanism – for making waggling movement with baskets under

liquid level during cleaning cycle due to ensuring

exposition of whole wafers surface by US waves and better washing away

impurities

Various manually operated

cleaning tank and lines.

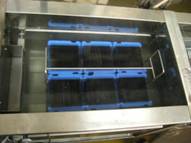

![]() Automatically operated cleaners:

Automatically operated cleaners:

They are suitable for mass producers. Transport of baskets with wafers

between tanks is full automatic while loading and unloading baskets

out of the line remains manual. The lines have modular construction which

allows us to add or take away modules under customers’

requirement. Cleaning power: 1500 wafers / hour when cleaning cycle take

6 min.

Automatically

operated cleaning lines, type UC 14M 95A.

Possible accessories:

- Baskets

- The Hot air dryer S 201

- System for automatic working liquids replacement

- Storage tank for hot DI water preparation MZH 001

- Baskets:

The automatic cleaning lines are designed to clean wafers positioned

into special stainless steel baskets. One basket serves for positioning

of 6 pcs of standard plastic cassettes for wafers. One plastic cassette

is for 25 pcs of wafers. It means one basket is determined for

max. 150 pcs of wafers. Various shapes and sizes are delivered (Baskets

under customers’ requirement are possible too).

- The

Hot air dryer, S 201:

The

Hot air dryer S 201 is determined for built-in into automatic cleaning

lines and serves for drying wafers at set cycle time.

- System

for automatic working liquids replacement:

The system

serves for automatic draining used liquids from before chosen tank and for

automatic filling the tanks by hot DI water.

Cleaning

agents are added into the tank manually. The whole replacement is executed

during next cleaning cycle standing it means

the

cleaning line can work continuously without stop due working liquid

replacement.

- Storage

tank for hot DI water preparation, MZH 001:

The equipment MZH

001 is designated to prepare required volume of hot DI water for automatic

replacement of working liquids

into automatic US

cleaning lines for cleaning wafers after cutting processes. The device mainly

consists of one storage tank for

DI water equipped

by electric heating system with temperature control by means of thermostat, one

pump for pumping (mixing)

DI water inside the

tank and a switchboard.

Except of the

in wafers production area:

![]() Spraying machines PC for precleaning wafers after

cutting processes:

Spraying machines PC for precleaning wafers after

cutting processes:

Immediately

after wafers are cut their surface is heavily contaminated by residual slurry

layers which are usually consist of cutting medium

(usually

oil or polyethyleneglycol), Si dust, SiC abrasive….. For removing of the big

quantity of the impurities it means for preliminary

cleaning

is the best using of spraying cleaning method mainly if the cutting medium is

glycol or combination spraying and immersion

cleaning

methods. Type PC 1M 200A serves for ungluing wafers by their immersion into

acetic acid too.

PC 1M 130

PC 1M 200A

![]() Ultrasonic cleaners for cleaning the silicon scrap

(raw material):

Ultrasonic cleaners for cleaning the silicon scrap

(raw material):

Ultrasonic cleaner, type UC 4M 50M is determined to clean the

silicon scrap (raw material) from impurities by means of ultrasonic

energy. The cleaning process

is under DI water or DI water solutions (with cleaning agent added). The

ultrasonic cleaning line consists

of two ultrasonic tanks, two

rinsing tanks, an automatic vertical transport system for automatic vertical

movements,

DI water regeneration station

of switchboard. The cleaning line is designated for cleaning the raw material

only

with special stainless steel

baskets.

UC

4M 50M Basket with scrap

![]() Hot air dryers:

Hot air dryers:

The dryers are designed for

drying wafers after cleaning. Two variant are produced by us:

- Independently standing

machines – type S 105, which are

determined mainly for manually operated US cleaning lines.

-

Built-in dryers – type S 201, which

are determined for automatically operated US cleaning lines.

The

dryers are determined for drying one basket with wafers it means 150 pcs of

wafers / 1 drying cycle.

S 105 S 201

![]() Mixers:

Mixers:

The mixers types H serve for cutting slurry preparation.

Our firm produce mixers with tank volume 400, 500 a 2000l or under

customers

requirements. The mixers

can be equipped by various equipments usually under customers requirements –

e.g. pump, timer...

H 400

H 500

![]() Spool cutting machines:

Spool cutting machines:

The

Spool cutting machines RD 001 are designed

for cutting used wire for spools of cutting machines for wire saw cutting.

Cutting

power is c. 18 spools / 8 hours.

RD

001

![]() References:

References:

JSC

PILLAR,

Silicio

Solar SAU,

PCMP

Podolsk,

Swiss Wafers, Weinfelden, Switzerland

KCMP,

Orlovka, Kyrgyz Republic

MBP mbH,

PTE,